表面处理剂

Surface Treatment Agents for Colored Steel Sheet Coating (Primer-free)

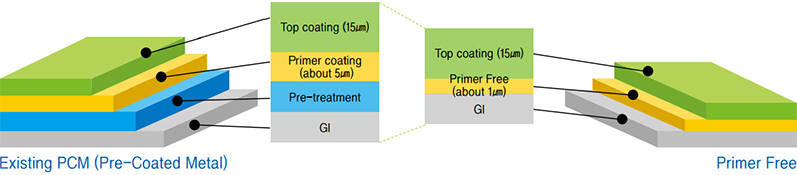

This primer-free coating agent is used to give the anti-corrosion function and better look to hot dip galvanized sheet sheets, Galvalume steel sheets, aluminum-coated tell sheets, electrolytic galvanized steel sheet, etc. Steel sheets are coated with primer-free agent and top coating only because pre-treatment and primer coating layers are integrated. Differently from the 3-layer coating of pre-treatment, primer coating and top coating, this process enables to function even on thin filmes which intergrated priver free coating layer with reduction of electric power consumption and colored steel sheet production cost.

Required Specifications

| Required Function | SPEC | Test Methods | |

|---|---|---|---|

| Coating amount | TOP | 15 ㎛ | - Using a dry film thickness measuring system, - Primer Free |

| Primer Free | 1 ㎛ | - Dry film weight | |

| Wear Resistance (MEK) | over 50 times | - Checking coating disbondment and color difference after rubbing by using methylethylketone | |

| Pencil Hardness | above F | - Checking hardness by using Mitsubishi pencil | |

| Impact Resistance | No crack | -Using Dupont impact resistance tester - Checking paint cracks or coating disbondment after dropping a 500g weight from a 500mm-high point |

|

| CCT | GOOD | - Checking coating disbondment with Erichsen 6mm & tape after CCT | |

| Machinability (T-Bend) | 2T-crack | - Checking the result of tape desquamation after 2T-bending | |

| Anti-corrosion (500hrs) | No corrosion | - Anti-corrosion test of plates | |

| 5mm | - Anti-corrosion test after X-cut | ||

| 20mm | -Edge anti-corrosion test | ||

Language

Language