- Global Buhmwoo

Global Buhmwoo

- Industries Served

- Social Responsibility

Social Responsibility

- PR

PR

Language

Language

Consumer Goods

>

Industries Served > BEX-INTER CORPORATION > Products

>

Industries Served > BEX-INTER CORPORATION > Products

Products

Electronic Materials

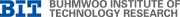

TFT LCD Process

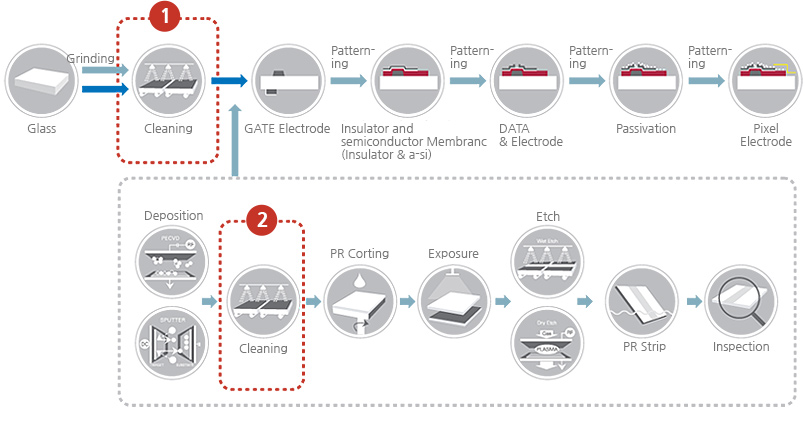

Array / Color Filter

This effectively removes fine particles existing before the evaporation process and oil pollutants produced during the process, so enhances the process efficiency and product yield. As a low-foaming type, it is suitable for ultrasonic steeping, spray and brush cleaning process.

| Items | Process | Property | Temp. for USE(℃) | Concentration for Use | pH | Features |

|---|---|---|---|---|---|---|

| GC3000HP | ①,② | Alkali | 30~60 | 2~5% | 12.5(3%) | Low-foaming type with excellent rinsing effect. Removes finger-prints and particles by alkali agent. |

| GC3022F | ①,② | Alkali | 30~60 | 2~5% | 12.5(3%) | Removes finger-prints. oil pollutants and particles through the chealting effect |

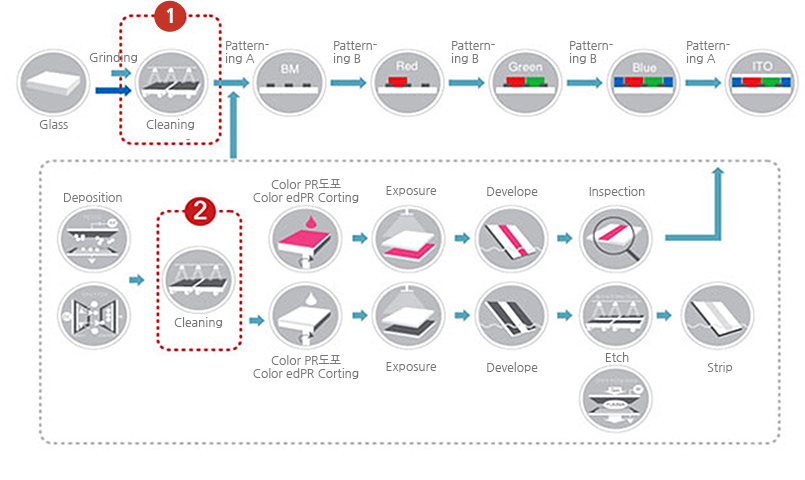

Cell Process

Using this, you can remove foreign materials on the glass surface which are produced after ITO coating, can form a uniform culture membrane through the effect of decreasing the surface tension, and can effectively remove fine particles and oil pollutants existing in the surroundings after panel pasting.

| Items | Process | Property | Temp. for Use(℃) | Concentration | pH | Features |

|---|---|---|---|---|---|---|

| GC3022F | ① | Alkali | 30~60 | 2~5% | 12.5(3%) | Removes finger-prints, oil pollutants and particles after ITO coating. |

| GC6120F | ①,② | Neutral | 30~60 | 1~10% | 7.5(100%) | Removes finger-prints, oil pollutants and particles |

| GC6000 | ③,④ | Neutral | 30~60 | 10~100% | 7.8(100%) | Removes liquid crystals, oil pollutants and particles from surfactants. |

| GC6100F | ③,④ | Neutral | 40~70 | 5~20% | 7.5(100% | Removes liquid crystals, oil pollutants and particles from surfactants. |

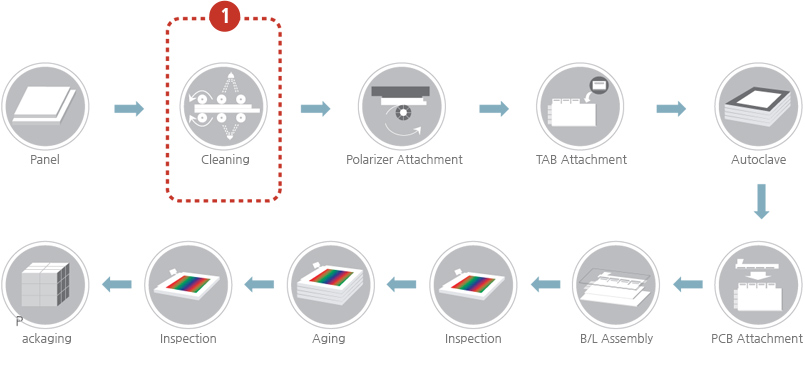

Module Process

These items remove fine particles before surface mounting of pasted panel so that the product yield is enhanced, and also remove foreign matters without any influence on electrode and materials because of being neutral type.

| Items | Process | Property | Temp. for Use(℃) | Concentration for Use | pH | Features |

|---|---|---|---|---|---|---|

| GC6000 | ① | Neutral | 30~60 | 10~100% | 7.8(100%) | Removes liquid crystals, oil pollutants and particles from surfactants. |

| GC6100F | ① | Neutral | 40~70 | 5~20% | 7.5(100%) | Removes liquid crystals, oil pollutants and particles from surfactants. |

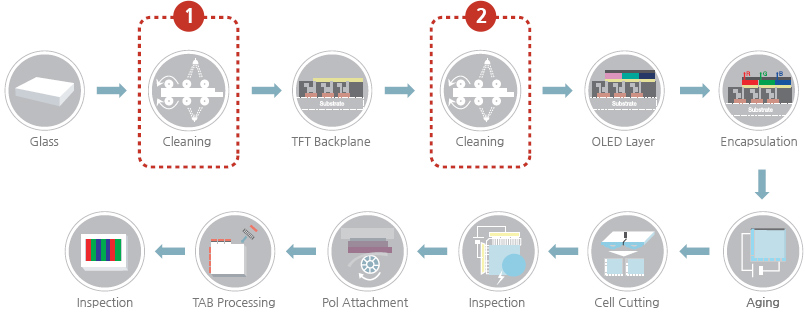

AMOLED Process

This is a process for products, which removes organic and inorganic particles existing on the glass board thus enabling an even surface treatment.

| Items | Process | Property | Temp. for Use(℃) | Concentration for Use | pH | Features |

|---|---|---|---|---|---|---|

| GC3022F | ①,② | Alkali | 30~60 | 3~10% | 12.5(3%) | Removes finger-prints. oil pollutants and particles by the chelating effect. |

| GC3000ER/EC | ①,② | Alkali | 50~60 | 3~10% | 12.5(3%) | Removes surfactants, solvents, oil pollutants, and remnants. |